Photo: www.espn.co.uk

If you are a motorsport fan, you probably have seen the practice sessions during a race weekend. They generally start on Friday and precede qualifying sessions. During the practice time, an inattentive watcher would say that the cars are just going around the track, randomly completing laps. Poor inattentive watcher.

A careful observer on the other hand, will see lap times improving during the many short periods where a race car stays on the track as the practice session progresses, until times get worse again, while the car stays on the track for a much longer period. “What is happening there?” – the careful observer would think.

Practice sessions are one of the most important aspects of racing, since they will enable race engineers to setup the car, giving the best result possible for qualifying and race. But, how do engineers use the (scarce) practice time to make their car faster? To answer this question, let us first have a brief look at the activities of a practice session.

Shakedown and Installation Lap

Shakedown test is the name given to the test period undergone by a race car before it can be declared operational. Shakedown is effectively the first test of the car and it is necessary to identify faulty components or systems of the car. It generally occurs during pre-season testing and mid-season testing (when new components are installed on the car) when the category regulations only allows for collective testing, such as in Formula 1.

The field of reliability engineering shows that, statistically, a proportion of the components of the car will fail in a relatively short period of use. However, the components that survive this brief period are expected to last for a much longer period. The shakedown is intended to identify these early failures and provide opportunities to counteract them.

During a shakedown, engineers will be concerned with data that can provide information on how the systems on the car are behaving, such as cooling, oil pressure, water and oil temperatures, fuel pressure and flow, fuel consumption, and monitoring of electrical and braking systems, among others. Everything being ok, it is time to take actual testing going on.

The installation lap happens on the first time a car runs on a given day. The procedure is quite simple: the driver will leave the pitlane, drive a single lap at a relatively slow pace, and drive straight back to the pits. During this time, the race engineer may ask the driver to follow certain procedures, or check specific systems, to make sure everything is working properly.

As the car gets back into the pits, the team will then check the entire car to make sure that all the systems are working properly before the driver goes back to the track for full speed running. During the check period, the team will look for signs of leakages and damaged or loose components. Data is also analysed during the installation lap itself, through the telemetry system, and after the car is back in the garage, through the data acquisition system.

In the highest levels of motorsport, oil samples will be taken from the engine and gearbox, for analysis by the oil supplier, at its mobile trackside testing facility. Data from these analyses will be ready very quickly, often during the relevant track session. These data serves the purpose of identifying excessive wear or contamination in the lubricants, which can indicate problems in the powertrain.

Installation lap checks will also include tyre pressure check. Any unexpected rise in tyre temperature may indicate a problem with the tyres configuration (even though tyres are pre-heated with tyre warmers before it goes to track, tyre pressures will increase significantly from the cold-tyres pressures, once the car is running).

If no major problems are identified after the installation lap, the driver is sent back to the track, to follow a predetermined program. Generally, this will consist of small runs with about five laps, where setup changes are made between them.

Practice Sessions

The practice sessions are periods where the teams are allowed to run the cars on the track for whatever they intend to do with the allocated time. One of the main differences between testing and practice is that other cars will be on the track at the same time (this difference will not exist at all for categories where the tests are collective). These sessions are a major contributing factor to a team success (or indeed, failure) as it allows for vehicle development.

This important track time will also help young drivers or newcomers to understand the relations between the changes made to the car and their effect on performance, allowing them to adapt quicker to the particular category. An important thing to remember is that every time a race car goes onto a circuit, the team will learn something new.

When entering into free practice, the team should have a base plan for changes that may be required. This will represent a busy period for the mechanics because the engineer and driver will need to try many different setup changes to improve lap times.

Practice sessions are very restricted in time, so that the teams must make the best out of the time available. Therefore, the team should plan the practice, so as to have fewer changes made towards the end of the session. Major changes such as tyre types or compound should be tested and not attempted in the last qualifying session.

Generally, most of the higher motorsport categories will have at least one practice session on Friday, and one on Saturday morning, before qualifying. Setting up the car for the Friday morning session can be tricky, as the track conditions can change dramatically between the first practice session and qualifying. On the beginning of the weekend, the track will probably be ‘green’ (in a low-grip condition, due to the lack of rubber on the track). Thus, an experienced team may not change setup to react to track conditions on Friday morning, as when the track has ‘rubbered in’ (get a higher grip levels) they will have to change the setup again.

In categories where individual testing is restricted, practice sessions can also be used to carry out components testing. In this case, a team wants to consider the time necessary to replace a component, in relation to the time available for the practice session. A change in wing or spring settings is easy and quick to do, but replacing the undertray of the car might take a much longer period. Therefore, teams generally test new components by doing all the work needed to install during the interval between sessions.

After the last practice session on Friday, the team will get the car ready for the qualifying on the next day. In categories where there is a limit on the number of engines and gearboxes used, these components are replaced for qualifying and the race, limiting the non-race units to Friday, in order to avoid putting unnecessary mileage on units used on the race. At the end of the day, engineers, drivers and managers will meet to discuss strategies and make significant decisions on the setup of the car for Saturday.

Setting Up the Car

Setting up the car is the main reason why practice sessions exist. The goal here is to optimize all the adjustable parameters of the car in order to get the best performance possible for qualifying and the race. This a complex process and involves many variables.

The race engineer will work together with the driver, by analysing his feedback and conveying it to the engineering team. This will be worked together with the data from the logging system, to provide the driver with what he needs to get his job done. To this point, data records from previous visits to the venue in question are used for reference while setting up the car. Before arriving at the venue, predictive tools (i.e. simulation) can be used to narrow the options to be used on track.

The main concern on setting up the car is to give the driver his preferred handling characteristics, which could be either understeer or oversteer. This could be achieved through many different options, and the balance of the car, as well as the driver preferences, could vary depending on the situation. For example, a driver might want a handling a little bit more prone to oversteer in a tight corner of the circuit, while preferring a little bit of understeer on a fast, large-radius corner of the track.

The oversteer/understeer balance of the car can be set through different ways, depending on the cornering condition. For low-speed parts of the circuit, aerodynamic downforce is less important, and thus the driver (and the engineer) will have to rely more on mechanical grip of the car. On faster sectors of the track, on the other hand, aerodynamic importance will increase, and a lot more concern on setting aerodynamic balance will be necessary.

Adjustment Parameters

Based on the above discussion on low-speed and high-speed handling balance, let us divide the major handling-interfering parameters to be adjusted into two classes, namely, mechanical and aerodynamic.

Mechanical Adjustments

Anti-Roll Bars

Anti-roll bars adjust the roll rate of the car. As noted here, altering the roll rate on an axle changes the weight transfer distribution of the car, and hence, its handling. The race engineer has the option to either change the stiffness of the anti-roll bar (when variable rates roll bars are available) or to change the entire bar.

Camber, Caster and Toe

Camber angle is the angle of inclination of a tyre generated by its rotation about a longitudinal axis. Toe, on the other hand, is the inclination of a tyre generated by its rotation about a vertical axis. Simply put, camber is the inclination of tyres when perceived by looking at the car from the front (or the rear) and toe is the inclination of tyres when perceived from top view.

Basically, camber and toe adjustments are used in order to keep the tyre working properly, i.e. work at the most appropriate angle to the ground (the angle that will maximize tyre contact patch area). Once a basic toe setup is made, it can be fine-tuned to give a sharper or blunter turn-in response (increase yaw rate or yaw damping, respectively, more on that on a future post about transient manoeuvring).

Increasing camber in a moderate fashion will cause the tyre to get upright when the vehicle rolls, thus increasing tyre contact patch area and, hence, lateral grip. On the other hand, on straights, the tyre contact patch will be reduced and so is the longitudinal grip.

Caster is the inclination in side view of the axis about which the wheel rotates when steered. It is seldom altered, because the changing process generally affects other parameters, thus, making setting up more difficult.

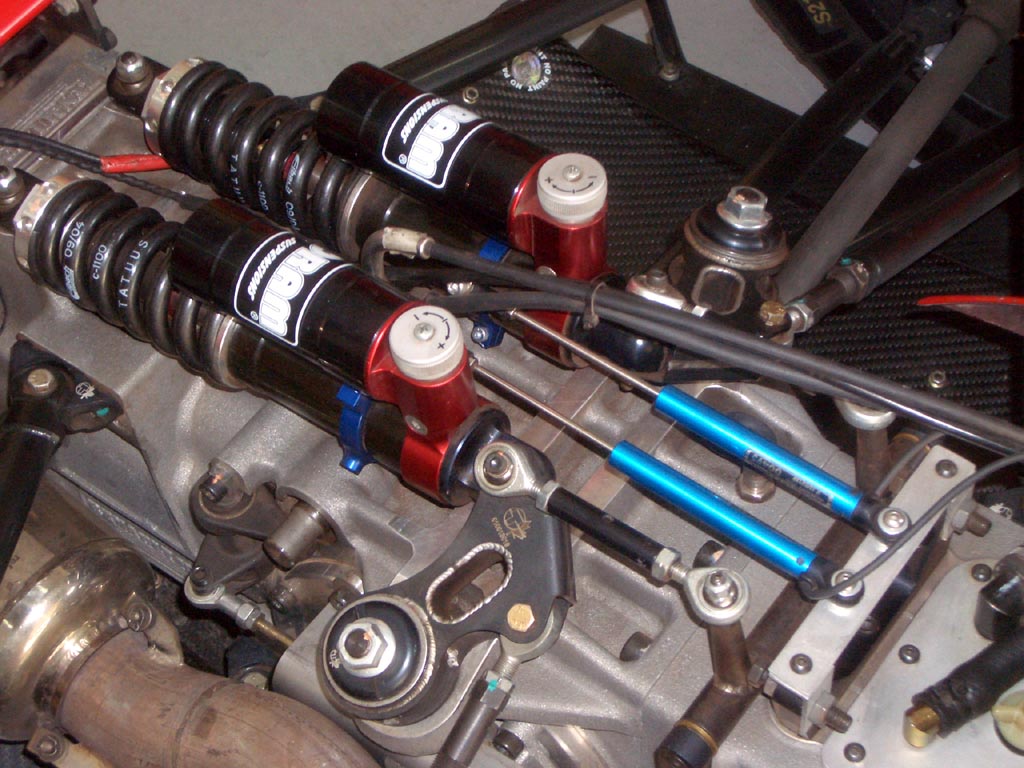

Spring and Dampers

Springs will also alter the roll rates of the particular axle in which they are installed, and hence can also be used to alter oversteer/understeer balance. However, the most important parameter related to springs on ground-effect race cars is probably the ride height control. Ground clearance will have huge effects on aerodynamic downforce. In general, the lower the car, the higher downforce will be. On the other hand, a lower car is at a higher risk of bottoming out (the floor of the car hits the ground), which will cause ground-effect-generated downforce to be significantly reduced, and thus making the driver lose control of the car.

Ballast

Ballast positioning is used to alter weight distribution on the car. This not only affects weight transfer distribution between the axles, but also upsets inertial forces distribution (centrifugal force being reacted by the tyres will be higher on an axle or the other).

Aerodynamic Adjustments

Ride Height

As stated before, altering ride height has a significant effect on the aerodynamic balance of the car. It is impossible to keep the ride height constant, as loads on the suspension are always varying with time. Thus, a compromise must be set for the specified track. When trying to reach such a compromise, it is important to mind the bumps on the track. They may require a higher ground clearance in order to avoid bottoming out problems.

The ride height setup is generally done such that the front ride height will be lower than the rear. This causes the undertray to ‘attack’ the air at a more nose-down attitude. The angle of inclination of the floor is called the rake angle, and it allows the floor and the diffuser to work in a more efficient manner to produce downforce. All in all, fine-tuning the ride height of the car affects the balance of the car, and tiny changes on this parameter, on the order of a few millimetres, can have a significant effect on balance.

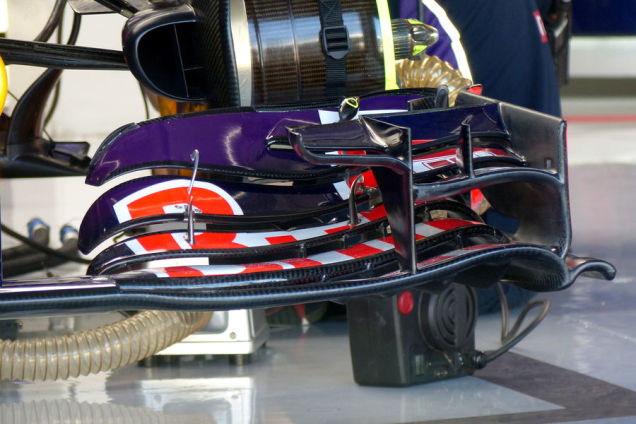

Wings

Wings can be set by adjusting their angle of attack (either the main plane or the flaps have their angles adjustable), the gap between the main plan and the flap (or between consecutive flaps) or even by using a different wing. Wing design may vary according to the circuit, and may represent low, medium or high-downforce configurations.

The characteristics of the wings may be mapped using CFD simulations and wind tunnel testing, and this allows the race engineer to quantify the parameters in order to choose the best combination of wing elements, their angles and gaps, to give the lowest lap times or desired end of straight speed.

Once the base aerodynamic setup has been established, fine-tuning of wings can be used to better suit the handling characteristics of the car to the driver’s preferences. The steeper the wing angle, the higher downforce and drag generated will be. This can be used to move the car’s centre of pressure (CP) forwards or backwards, which can affect the balance of the car.

Brakes

Adjustment of brake bias is an important tool to set the balance of the car. In many categories, brake bias can be changed from inside the car, and although a base setup for brake bias is defined as part of the general tuning procedure, fine-adjustments of brake bias can be carried out by the driver.

Brake bias is not only circuit-dependent, but also corner dependent, and the driver will often adjust this parameters between corners during a lap.

Gearing

Many categories will allow changes on gear ratios in the transmission. This is done by replacing gears inside the transmission (of course, this is a time consuming activity, and thus, its inclusion in a practice session should be carefully thought). This is always dependent on the circuit, and the procedure for gears selection is quite straightforward.

The lowest ratio (first gear) is selected so as to provide the highest acceleration possible out of the slowest corner on the circuit. The highest gear will be chosen to approach rev limit at the end of the longest straight. The intermediate gears will then be selected to be evenly spaced between first and highest gear, so that engine is kept as close as possible to its optimum power band.

Tyres

The most important goal of tyre setup is to keep temperatures and pressure within the manufacturer recommended operating window. If temperatures are somewhat out of this window (too hot or too cold), the level of grip will drop dramatically. Ideally, the tyres would also have the maximum contact patch area possible, which would help increasing grip.

When setting up the tyres, the race engineer will always look to have equal tyre temperatures at all four corners of the car, with even temperature distribution across the tyre tread.

Planning a Practice Session

Testing and practicing success will boil down to one word: planning. A race engineer should always create a detailed practice plan to obtain the maximum benefit from a session. Planning a test requires a logical approach. First of all, engineers will write down a list of ideas of what they would like to try. Preparation of testing session so to reduce testing costs is a good practice, and should be encouraged. For example, components that don’t directly affect each other should be tested simultaneously, using track time in a more cost-efficient manner.

After guaranteeing that all the systems on the car are working properly (installation lap), one should strive to establish a baseline setup. At this point, data from a previous visit to the particular track will provide solid guidelines on where to begin, especially in what concerns gear ratios. If this is the first time visiting the particular racing venue, gearing and initial setup can be estimated by comparison with similar known tracks, for which data is available. Here, it is important to notice that a gain in performance obtained during the test will redefine the baseline setup for the next race.

Then, fine-tuning of the handling to suit the driver’s needs and track conditions or experimenting for increased performance should be done. Finally, the most important aspect of practice test is proving the theory. So, it is imperative to do back-to-back tests for most items. For example, if lap times were improved by using different tyres, the engineer should find out if the gain in performance was due to a better performance from the tyre, or if track conditions changed, increasing grip. Quickly running a few laps with the original tyres will prove the performance difference.

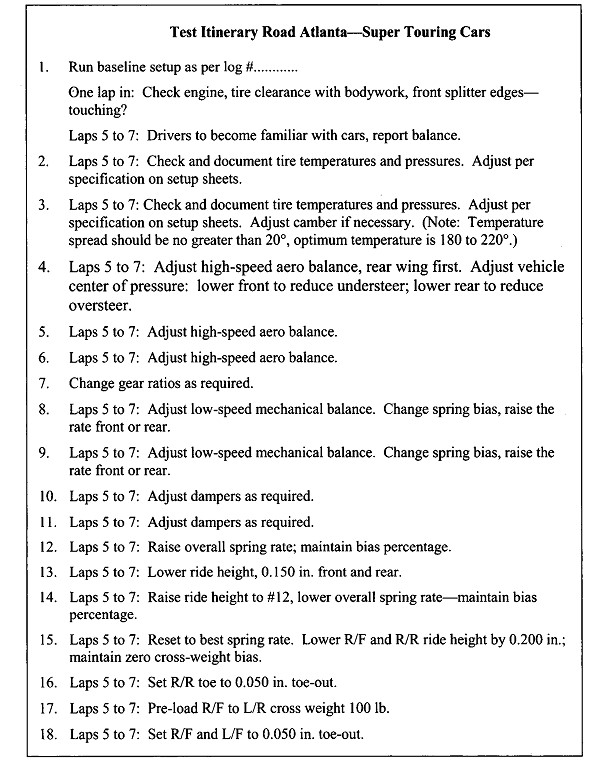

As practice itinerary should be as the one shown in the figure below. This schedule was taken from the book Hands-on Race Car Engineer, from John H. Glimmerveen. It describes the planning for a two-car team of Super Touring cars, used in the North American Super Touring Car championship. For this test, one of the cars had already been tested, and the lessons learned from that test had been incorporated onto the second car. The schedule is actually for a test session, but the principles also apply to practice.

The step-by-step explanation of the above testing is described below. During this session, all intervals on the track were limited to between five and seven laps because this number of laps gave meaningful tyre temperatures and pressures. Effective flying laps would be between three and five, due to “in and out” laps.

- A logbook made to record relevant information and help synchronizing data for later analysis. An installation lap will be carried out and the information gathered there is limited. Items for the team to check include whether the tyres hit the bodywork under dynamic loads, and if splitter edge had touched the track.

- The first reading of tyre pressures and temperatures is conducted. Any adjustments to the tyres at this point will be limited to pressure changes. If the pressures are greater than those recommended by the manufacturer, the center of the tyre will show a higher temperature. The opposite will be true if pressure is too low (outsides of the tyres are hotter).

- When the car returns, temperatures and pressures would be checked again. If the recorded information is meaningful (i.e. initial adjustments are not incorrect), then adjustments to camber could be made in an attempt to obtain an even temperature spread.

- After being satisfied with tyre temperatures and heat spread (which means correct settings for pressure and camber), the engineer will start to work out the understeer/oversteer balance of the car. This could be done by adjusting mechanical balance (springs and anti-roll bars) or aerodynamic balance. In this case, the engineer chose to go with aerodynamics first.

- The aerodynamic configuration is complex to obtain, and hence, the engineer planned several balance readjusts to find the best compromise between cornering performance and straight-line speed.

- At this point, aerodynamic balance should have been optimized, possibly requiring only fine-tuning.

- When the aero configuration had been finalized, the cars probably will need gear-ratio changes (this should not be done in the middle of a practice session unless extremely necessary, due to the short time available).

- The low-speed mechanical balance can now be adjusted through changes in spring rates and anti-roll bars rates.

- Depending on the results from previous step, the springs can now be optimized.

- Prior to the test, damper valving would have been set, normally based on the recommendations from the manufacturer. Thus, only small adjustments should be required.

- Further adjustment is made if required.

At this point, the car should have a good mechanical and aero grip, and the gearing optimized, so it’s time to implement a series of changes to know how they will affect performance. This is illustrated by steps 12 to 18, where the engineer will accumulate knowledge on the behaviour of the car after various adjustments. This is only done in a practice if the team is use the track time to test new parts or systems.

During the tests, it’s important to tell the driver what changes are being made, and why they are implemented. The driver will not only be ready for the changes, but also will develop a better understanding of the behaviour of the car after any changes.

It is important to notice that practice sessions will serve the purpose of setting up the car for two completely different situations: qualifying and the race. Some parameters will be set completely different for each of these situations, and generally this is assessed during practice two.

First, a qualifying will make things much easier for the driver, since it is easier to out-qualify thirty cars than to overtake them. If the rules of the category allow, a setup specifically for qualifying will be required. For this setup, a lot of components will be lighter and/or more efficient, at the expense of durability. Hence, the fuel load will be much smaller, reducing the weight of the car, tyres will be softer (and with more grip, but also higher wearing), oil levels will be kept as low as possible, brake pads will be softer and thinner, and so on.

For race, the setup will obviously have a much higher demand on durability than on performance, and the configuration of the car will be totally changed. Race settings are tested during practices in longer runs. During these runs, the driver will go to the track in a race configuration, and stay on the track during a much longer period, completing several laps, in order to evaluate race situations. This is generally carried out from second half of the session, and that is the reason why you see lap times increasing towards the end of practice.

On the next posts on Race Engineering, I will talk about how the individual parameters of the car should be tuned, in order to achieve maximum performance, and how other track activities are done. You don’t want to miss that, do you? Then, please keep in touch with Racing Car Dynamics, by subscribing to our email newsletter below. See ya! 🙂

KEEP UP TO DATE

KEEP UP TO DATE